Optical design and optical performance analysis technology

MPNICS ensures productivity and technical reliability by applying asymmetric optical design and tolerance analysis technology based on optimal optical simulation.

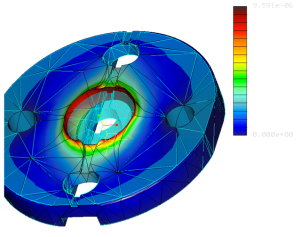

Finite element analysis and shape correction technology of lens and mold

MPNICS offers products that are close to design by optimizing the lens mold through MPNICS’ independently developed technology of form error compensation.

Ultra precision mold processing technology

Through the use of ultra-precision aspherical shaping equipment, the surface roughness of the product is improved to the nanometer level, which brings the result of improved product performance as well.

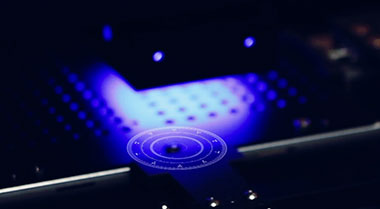

Micro-glass optical component molding technology

Through ultra precision high temperature high pressure optimum molding technique, we offer products with Ø1.0 ~ 20 ㎜ thickness. We possess 0.1mm ultra-fine lens shape molding technology.

Optical thin film design and deposition technology

Optical components are equipped with the characteristics of optimal transmission and reflectivity through optical thin film design and thin film deposition.

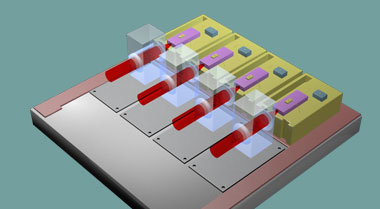

Micro-optical component package technology

By evaluating and analyzing laser light source and optical parts, fabrication of optical sub assembly can be supported.